AdamIQ™ 17-4PH

AISI 17-4PH | W. Nr 1.4542 | DIN X5CrNiCuNb16-4 | UNS S17400

Premium stainless-steel powder, AdamIQ™ 17-4PH offers high strength and durability with excellent corrosion resistance. Perfectly suited to be printed in any powder bed fusion machine (L-PBF, SLM). The final end-use properties and hardness can be fine-tuned in post-printing heat treatments.

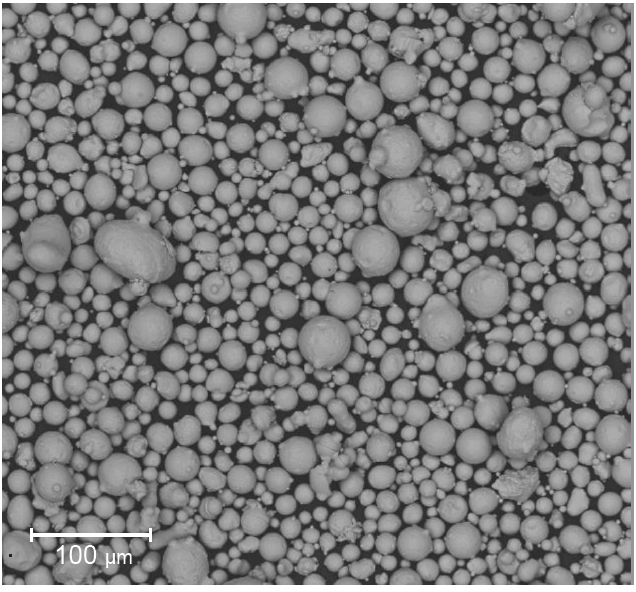

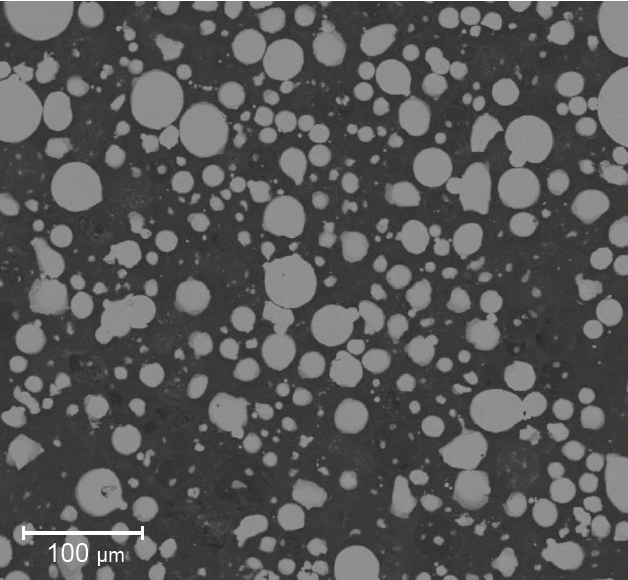

Made from 100% recycled steel and renewable energy. Spherical, with high flowability and low level of impurities.

This great blend of properties makes it an excellent candidate for the widest possible range of applications, especially at elevated in-use-temperatures, up to 300°C (572°F), including rapid tooling functional components in nearly every market.

Additionally, 17-4 PH is widely used in environments where a level of corrosion resistance comparable to that of the austenitic grades is needed, but in applications that require higher strength and hardness than the austenitic grades can provide.

A version that meets aerospace standard is available.

Main applications

Surgical instruments

Valves & engine components

Acid and corrosion resistant technical parts

Specific Tools and Molds

General engineering

Markets

Aerospace

Automotive

Chemical

Consumer goods

Energy

Petrochemical

Transportation

Powder properties

AdamIQ™ 17-4PH

Chemical composition in weight % (1)

Iron | Balance | Silicon | < 1.00 | |

| Chromium | 15.00 - 17.50 | Nitrogen | < 0.10 | |

| Nickel | 3.00 - 5.00 | Oxygen | < 0.10 | |

| Copper | 3.00 - 5.00 | Phosphorus | < 0.04 | |

| Niobium + Tantalum | 0.15-0.45 | Carbon | < 0.07 | |

| Manganese | < 1.00 |

| Nominal particle range | 20-53 μm |

|---|---|

| Apparent density (2) | 4.1 g/cm3 |

| Hall flow (3) | 20 s/50g |

Also available in particle sizes:

• Less than 20 microns for Binder Jetting (BJT), Metal Injection Molding (MIM) or specific processes targeting very thin walls.

• 53-105 microns typically for Electron Beam Melting (EBM, E-PBF) and Laser Metal Deposition (LMD).

• Specific sizing can be considered under conditions.

--

(1). Composition fits ASTM A564 Type 630; AMS7012 can be studied on demand

(2). Apparent density according to ASTM B212

(3). Hall Flow according to ASTM B213

Packaging and handling recommendations

- Recycled and recyclable drum from CurTec (minimum2.9 L / 10 kg). Sealed, includes desiccant bag.

- Big bag solutions available on demand.

Ensure that you store the product in its original container in a dry area. Before using, gently tumble to prevent any segregation. If you have opened containers, it is recommended to store them in a drying oven or a controlled environment with low humidity to prevent any moisture pick up.

*Technical data and information are to the best of our knowledge at the time of publishing. However, they may be subject to some slight variations due to our ongoing research programme on steels. Therefore, we suggest that information be verified at time of enquiry or order. Furthermore, in service, real conditions are specific for each application. The data presented here are only for the purpose of description, and considered as guarantees when written formal approval has been delivered by our company. Further information may be obtained from the address mentioned.

AdamIQ™ 17-4PH

Premium stainless-steel powder, AdamIQ™ 17-4PH offers high strength and durability with excellent corrosion resistance. Perfectly suited to be printed in any powder bed fusion machine (L-PBF, SLM). The final end-use properties and hardness can be fine-tuned in post-printing heat treatments.