Productivity as a service

Count on us to boost your Additive Manufacturing experience

At ArcelorMittal Powders we understand that productivity is the most significant issue in Additive Manufacturing. The machines are expensive, and depreciation drives up the cost of parts produced, so maximizing the output of the equipment is the best way to drive down costs per part, which also broadens the range of applications where Additive Manufacturing can be used.

Our focus on productivity means that we not only offer Steel Powders for Additive Manufacturing, but also many other printing-related services, such as parameter set optimization on request, load management, print Speed and bulk file Optimization on request (available on Renishaw RenAM 500 /and Additive Industries MetalFAB1). *

Example: case study

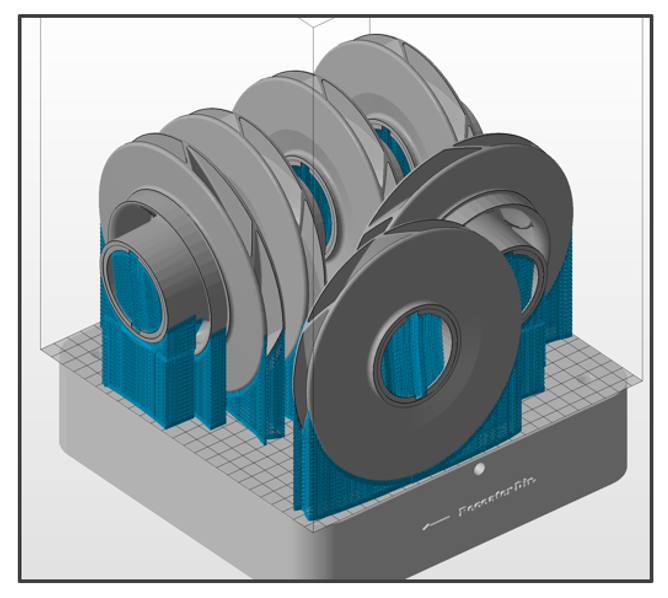

Industrial Impeller Buildjob

- Material: 17-4 PH

- Machine: RenAM500Q

- Packing density: 17.5 %

- Layers: 2,688

- Layer height: 60 microns

- Power: 300 W

- Speed: 1000 mm/s

- Pitch distance: 0.1 mm

Fig. 1 Real industrial build job for ArcelorMittal spare-part R&D project done in 17-4PH in the Renishaw500Q. Source: ArcelorMittal Global R&D 2023.

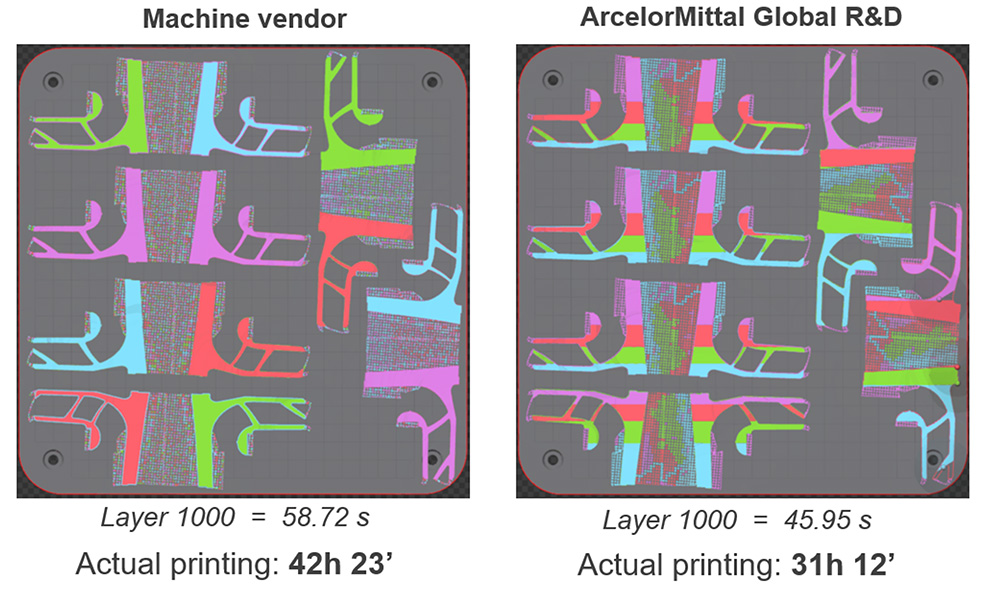

As illustrated in Figure 1, the build job comprises six impellers, each mounted on its respective support structure on the build plate of a Renishaw 500Q machine. Figure 2 highlights the significance of load balancing among the machine's multiple lasers by comparing the standard optimization offered by the machine with the optimized solution provided by ArcelorMittal.

Fig. 2 Multilaser vector assignment for the industrial buildjob previously introduced. In the left the standard machine solution and in the right the optimization achieved by ArcelorMittal solution. In both cases the same layer is shown. Both times, layer time and total printing time are compared. Source: ArcelorMittal Global R&D 2023.

ArcelorMittal solution is 26.2 % faster

We are committed to your productivity

Contact our experts to know how we can help you boost your Additive Manufacturing experience.