White Paper 1: Novel approach to increase LPBF productivity

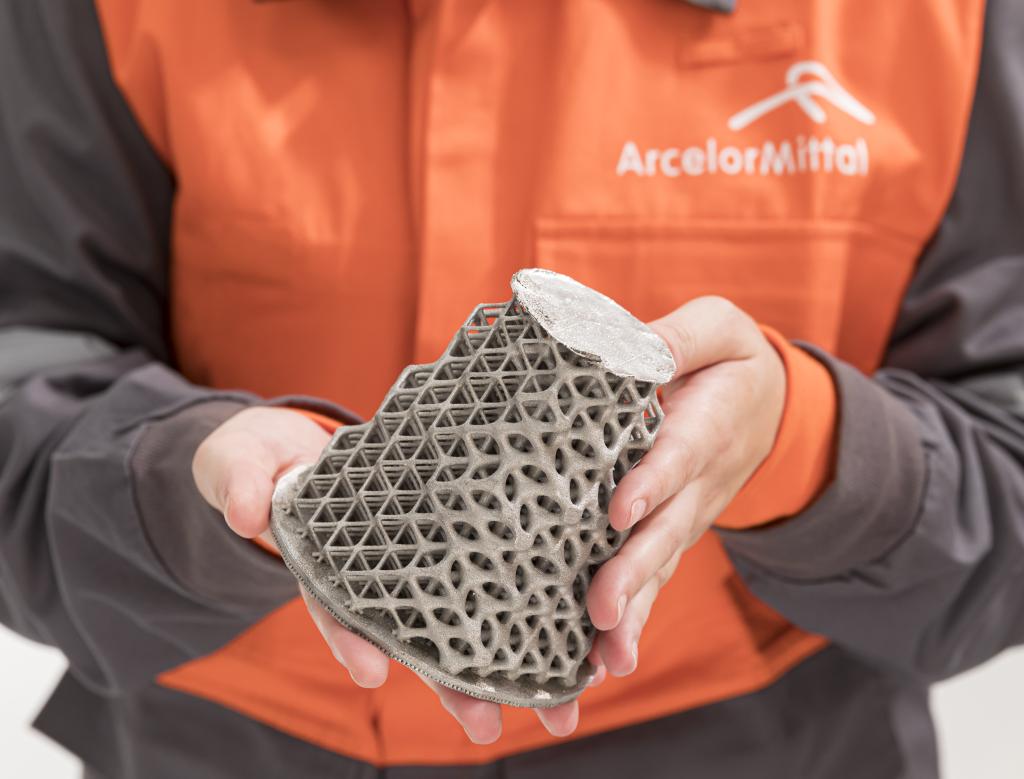

ArcelorMittal has developed significant expertise in metal additive manufacturing, 3D-printing of spare parts and the technologies used to manufacture parts. Some of this expertise is shared in a series of white papers.

Productivity is the most significant issue in additive manufacturing. The machines are expensive and depreciation drives up the cost of parts produced. Maximising the output of the equipment is the best way to drive down costs per part, which also broadens the range of applications where additive manufacturing can be used.

Laser Powder Bed Fusion (LPBF) is the most widely used additive manufacturing technology for producing metal parts, layer-by-layer. A common approach to define the most productive printing conditions for a given material on such an LPBF system is to create maps of material density versus the volumetric energy density of the process.

The material density achieved is taken as a proxy for the achievable part quality. The volumetric energy density (VED) is the amount of energy delivered to a given volume of metal during the LPBF process and is used as a criterion to select the best operating parameters for a material. The typical approach to maximising the productivity of LPBF production is to choose the processing parameters that give the lowest VED, for a given part density.

ArcelorMittal R&D’s experience is that more is possible. A lot more.

Since 2018, ArcelorMittal R&D has been exploring the potential of additive manufacturing to optimise the production of spare parts. A novel approach has been identified which builds on the VED/density mapping idea but accommodates other factors such as the design of the part to be printed and the printing strategy used. In an example business case, a spare part is printed on a single-laser LPBF.

With 24 parts fitting on the build plate, the packing density of the build job was just under 20% which is a normal level for serial production. Compared to the typical approach of VED/density mapping, the novel approach increased the average build rate per layer by 50%.

Interested in the White Paper or have questions?

Download this White Paper or contact our experts on Steel Powders for Additive Manufacturing!