New White Paper released

White Paper 2: Does powder quality really impact LPBF performance?

- About us

- Newsroom

November 15, 2023

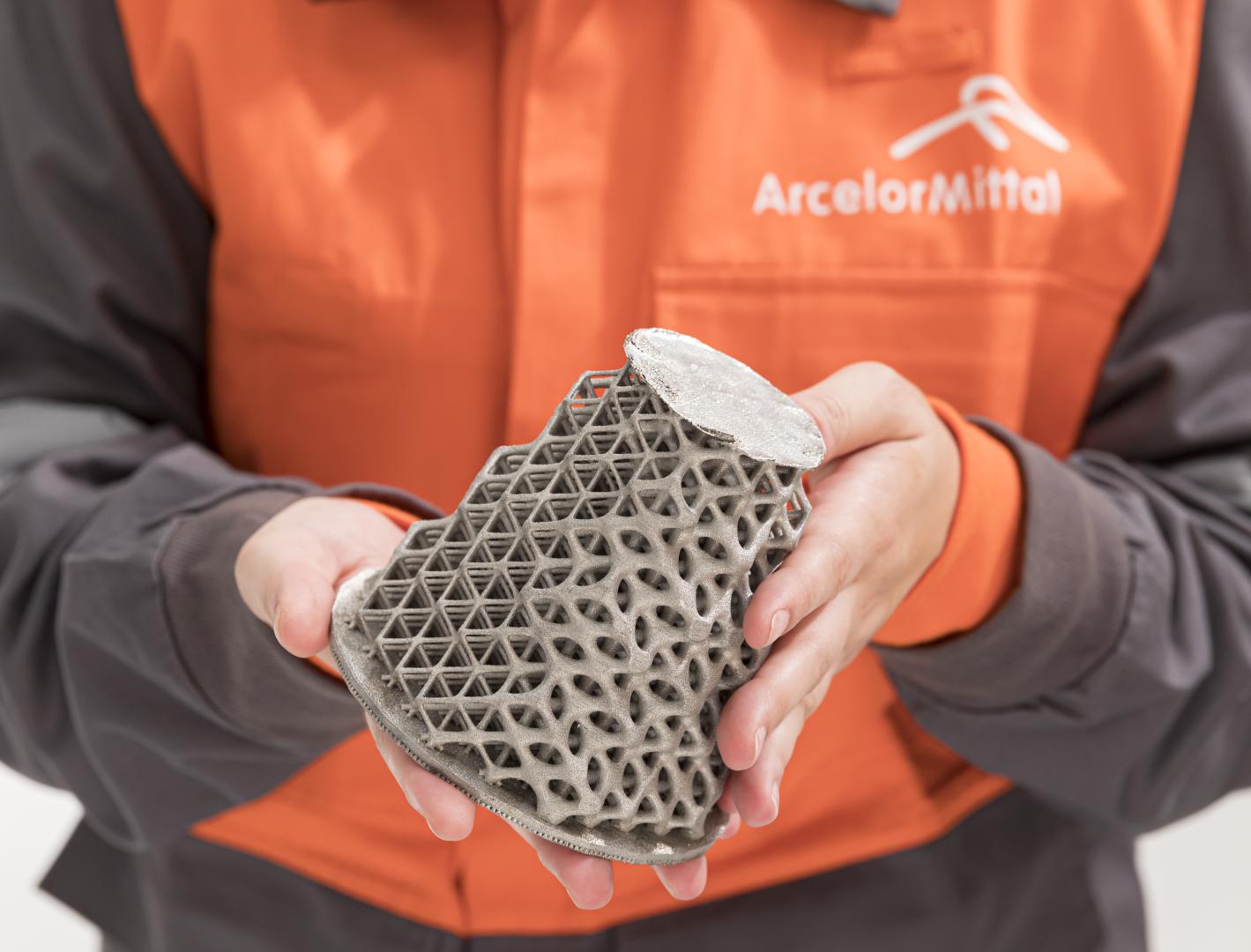

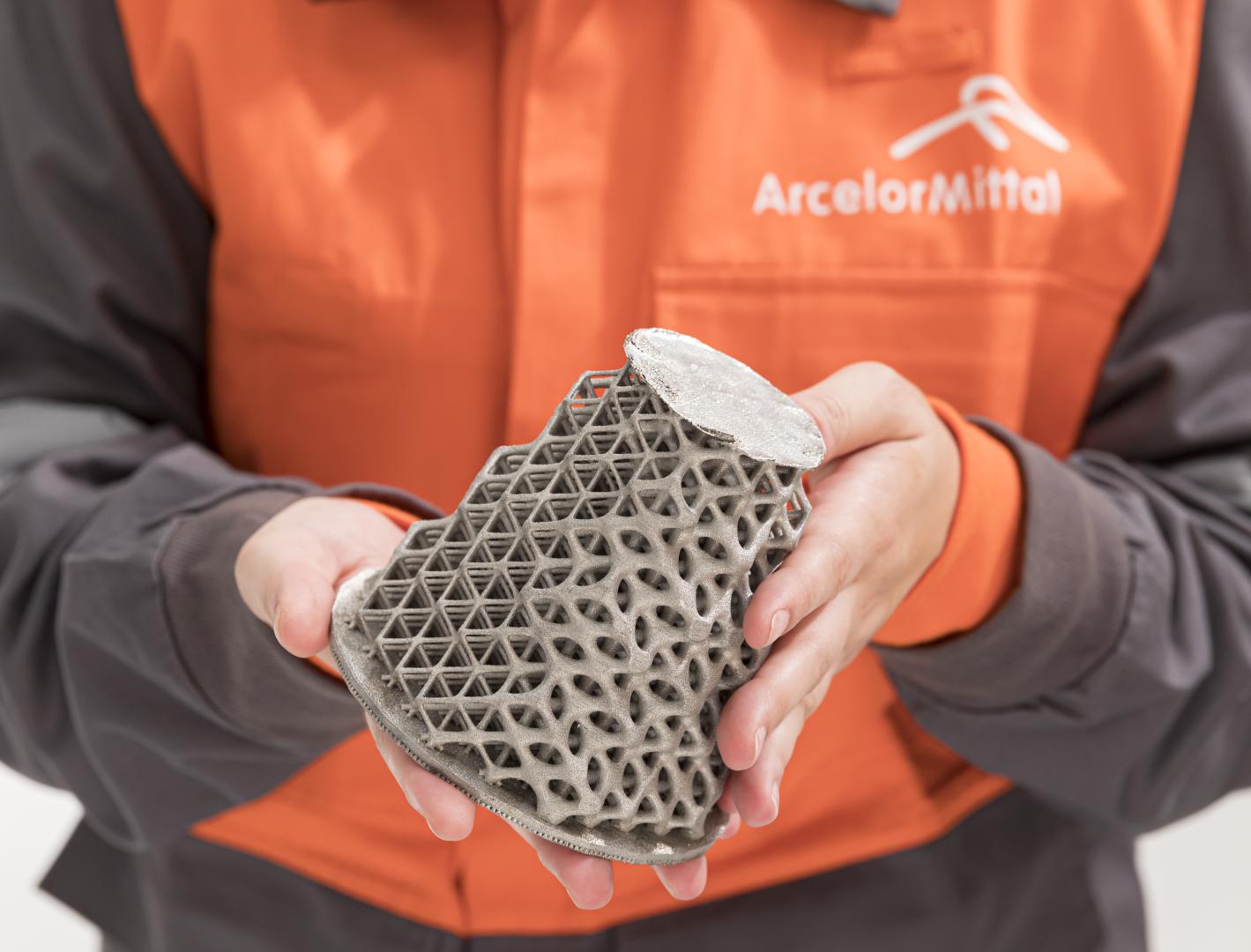

ArcelorMittal enters the additive manufacturing industry as a steel powder supplier

The company is building an industrial-scale atomiser in Spain to produce high-quality steel powders for multiple additive manufacturing technologies

Find out more

News

November 13, 2023

ArcelorMittal Powders supports Euro 7 and particle emissions reduction from brake discs with AdamIQ™ Steel Powders

At our stand in Formnext we have shown how we can help the Auto Industry reduce fine particle emissions from brakes, following Euro 7 regulation that is to apply from 2025-2026.

Find out more

News

November 09, 2023

ArcelorMittal Powders and Sicnova conclude an order to supply Steel Powder for a strategic defence project

ArcelorMittal Powders is honoured today to receive a 5.tons order for its AdamIQ™ Steel Powders that will support Sicnova, Spain's leading distributor of 3D printing and 3D scanning technology, for the supply of additively manufactured parts for a confidential defence project.

Find out more

News

October 30, 2023

Visit us at Formnext 2023!

From November 7 to 10 in Frankfurt (Germany), visit our stand at the world's leading trade fair for Additive Manufacturing and industrial 3D printing, Formnext, and you will discover how we are going to serve this industry.

Find out more

News , Events

September 01, 2023

White Paper 2: Does powder quality really impact LPBF performance?

In this whitepaper, we present the results of an experimental study that addressed these questions. We compared the performance of 316L stainless steel powders from two different suppliers, using two different printing strategies, on a MetalFAB1 4-laser system from Additive Industries. We measured the density and build rate of the printed parts, as well as the PSD, morphology, and chemical composition of the powders. The results were surprising.

Find out more

News

July 20, 2023

Paris 2024 Olympic and Paralympic Games torch revealed

To manufacture the Torch for the Paris 2024 Games, ArcelorMittal is mobilising its Global R&D department and three of its French sites to represent the expertise of its workforce.

Find out more

News

May 02, 2023

White Paper 1: Novel approach to increase LPBF productivity

ArcelorMittal has developed significant expertise in metal additive manufacturing, 3D-printing of spare parts and the technologies used to manufacture parts. Some of this expertise is shared in a series of white papers.

Find out more

News

March 28, 2023

Steel 3D printing technology applied in a Dakar Rally vehicle

The 3D printing technology used by ArcelorMittal at its R&D&I Centre, combined with the smart design algorithms of Nebrija University, made it possible to develop various components of this Dakar Rally car. Nebrija University students undertook the redesign and technological improvement of a car of the Sodicars team that took part in the 2023 Dakar Rally in the top-class category (T1).

Find out more

News , Engineering , Automotive

February 25, 2022

ArcelorMittal and Nebrija University use 3D printing to build a motorbike chassis

This close collaboration between ArcelorMittal and the Materials and Advance Manufacturing research group (MOD3RN) at Nebrija University has led to the manufacture of a steel chassis that could revolutionise the motorbike world

Find out more

News